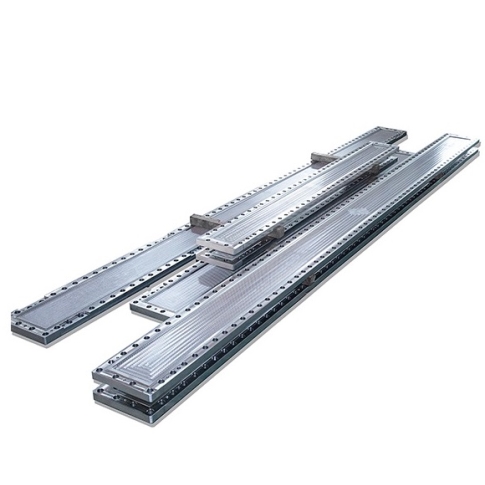

spunbonded spinneret

| ODM / Melt Blown / Chemcial fiber / Spandex Spinneret Litlhaloso | |||||

| Dia.Of Spinneret Capllaries/D | L/D Ea Spinneret Capillaries | Dia.Of Spinneret Capllaries Mamello | Bolelele ba Spinneret Capillaries Tolerance | ||

| Kereiti e Nepahetseng | Height Precise Kereiti | Kereiti e Nepahetseng | Height Precise Kereiti | ||

| 0.04-0.1mm | 1/1-5/1 | ±0.002 | ±0.001 | ±0.01 | ±0.02 |

| 0.1-0.5mm | 1/1-5/1 | ±0.002 | ±0.001 | ±0.01 | ±0.02 |

| 0.5-1 limilimithara | 1/1-10/1 | ±0.002 | ±0.001 | ±0.01 | ±0.02 |

| 1-2 limilimithara | 1/1-20/1 | ±0.004 | ±0.002 | ±0.02 | ±0.03 |

| Chamfering ea lesoba la tataiso | N5-N7 | ||||

| Tataiso Hole | N3-N6 | ||||

| Angle e Feteletseng | N2-N6 | ||||

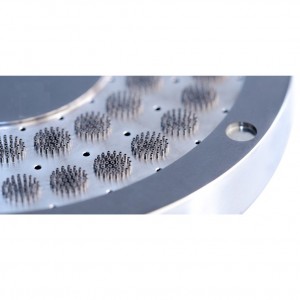

| Li-capillaries | N1-N3 | ||||

| Seipone Pholisitse | N1 | ||||

| Ho sila | N2-N4 | ||||

Haeba u batla ho etsa ho hong ho betere, u tlameha ho chola sabole ea hau pele.

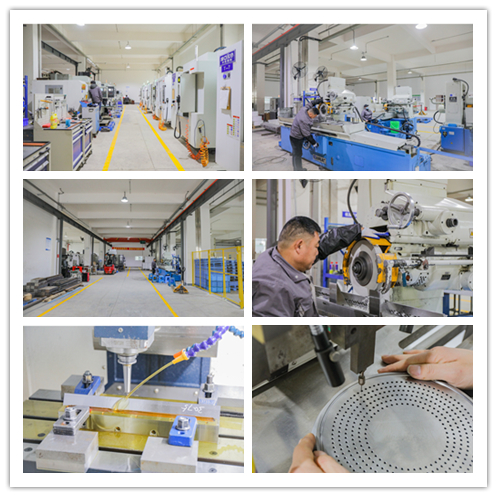

Ntlafatso ea sehlahisoa se secha le tokollo ke matla bakeng sa nts'etsopele e tsoelang pele ea k'hamphani, SSPM Spinneret ke k'hamphani e elang hloko haholo sena. E leka ka hohle ho fa bareki ba eona moralo oa morao-rao le ho lula ka pele ho lik'hamphani tse ling tsa mofuta oa eona.

Boleng ke senotlolo sa thekiso ea lihlahisoa. Ho ipapisitsoe le tumelo e phahameng ea netefatso ea boleng, khoebo e kentse lisebelisoa tse felletseng tsa tlhahlobo le liteko tse tsoetseng pele, tse shebileng mohatong o mong le o mong o monyane, o phehellang ts'ebetsong e felletseng ea taolo ea boleng, ho theha boemo ba taolo ea boleng ka ho kenya letsoho ha basebetsi bohle le boikarabello ba maemo ohle ka tšebelisano-'moho le ho lekola lipakeng tsa liphatlalatso tse fapaneng tsa likarolo tse fapaneng tse hlophisitsoeng bakeng sa taolo ea boleng bo fapaneng.

Khamphani e nka bohlokoa ba ntlafatso e 'ngoe le e 'ngoe ea boleng joalo ka ha ho ela hloko ntlafatso ea setšoantšo sa eona se akaretsang mme k'hamphani e se e netefalitsoe ke sistimi ea boleng ea ISO9001.

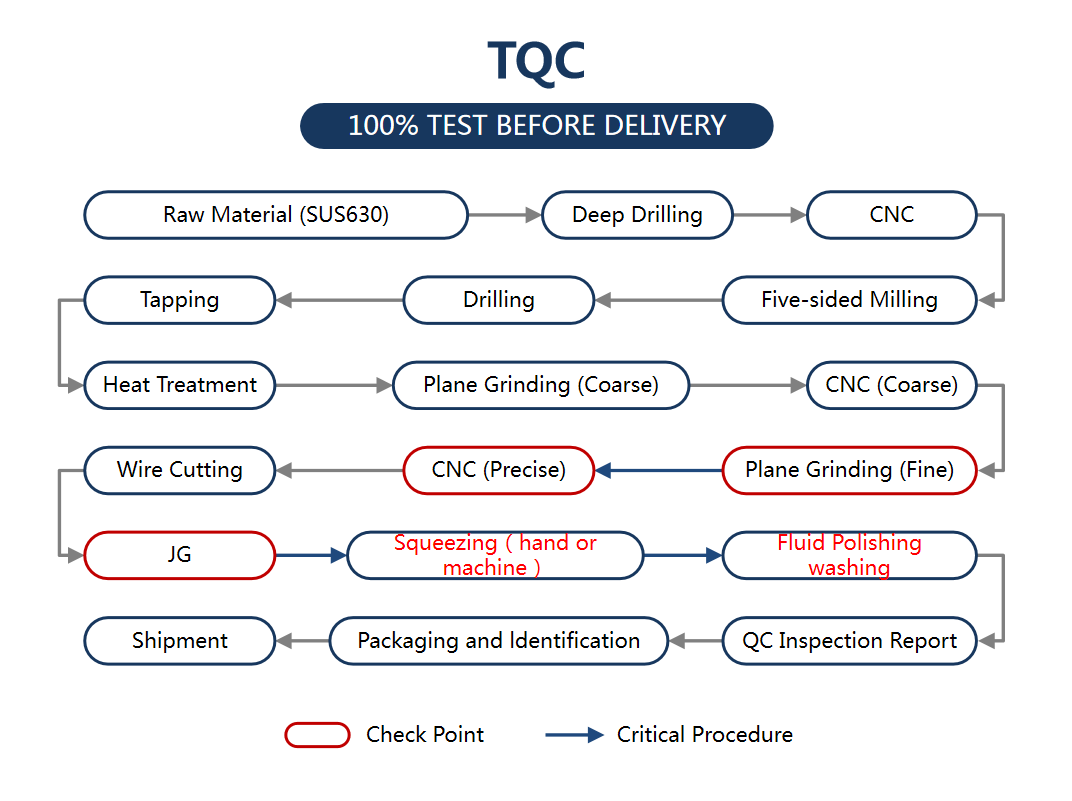

Mohala oa Tlhahiso

Mokhoa oa Tlhahiso ea Spinneret

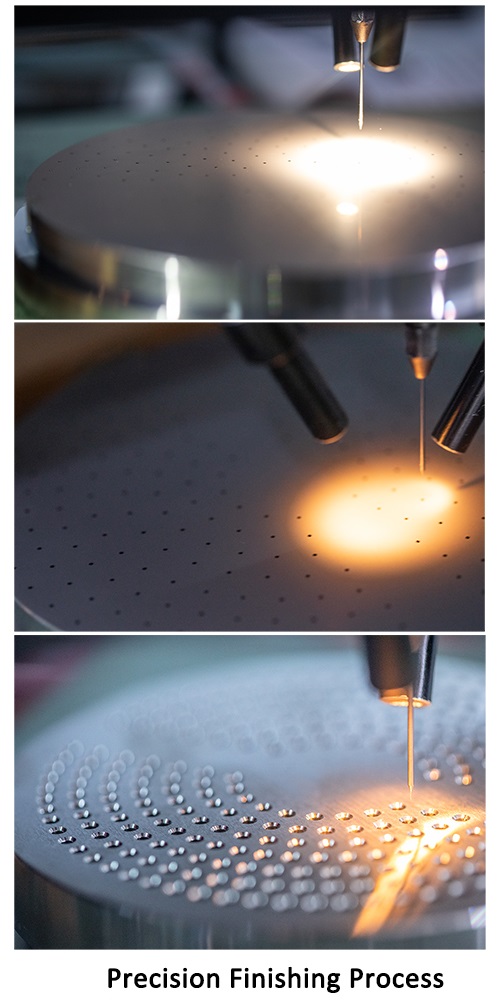

Spinneret Precision Finishing Process

Lisebelisoa tsa Tlhahlobo ea Spinneret